The uprise of Rafale II

The C-Class was born in 1961, when the British catamaran designer Rod McAlpine-Dowey became aware of a challenge that came from America and claimed to have ‘the fastest boat in the world’. Rod responded to the challenge and simple rules were agreed - loosely based on those of the America's Cup.

Since then, the C-class has been THE guinea pig on which tomorrow's technologies are tested, contrasted, compared, validated and implemented into the major sailing classes. One example is the rigid sail. Now adopted by the America's Cup boats, the rigid sail was developed right for the C-Class as early as the '70s. The C-Class catamaran has a length of 7.62 meters with two symmetrical hulls - spaced 4,267 meters -, a sail area of 28 square meters and 2 crew members to the trapeze.

The International C-Class Catamaran Challenge, better known as the Little Americas Cup (a series of match races between two catamarans), actually has more than one point of contact with the America's Cup, one can say that the Little Americas Cup is the laboratory of the elder sister: the America's Cup.

High tech project on low budget

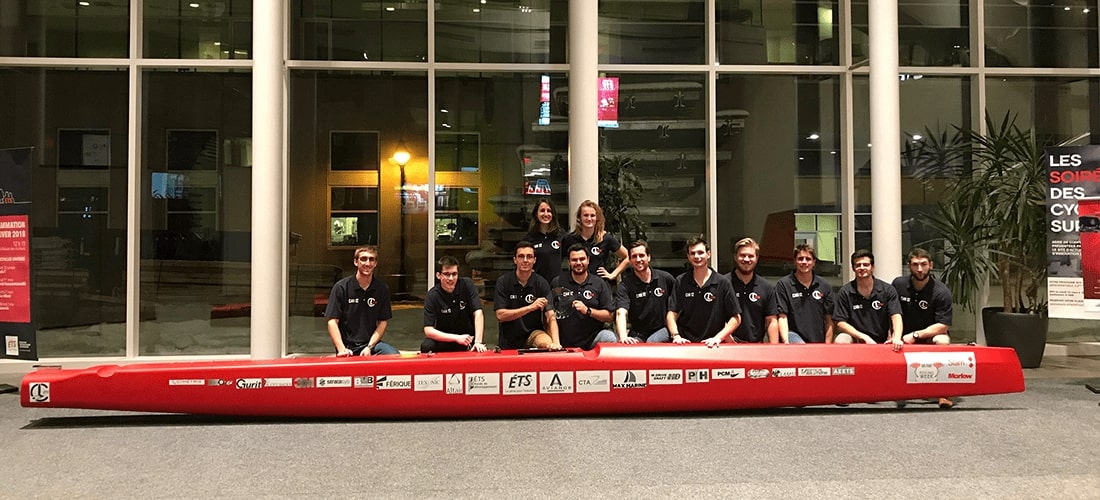

Sports-wise, this championship brings together the biggest names in international sailing as well as the America's Cup contestants. Which is why the participation of a low budget university team in 2014, was particularly interesting. ‘Rafale’ – translated from French meaning Wind Gust - was the name of the Quebec team that designed and built a C-Class Rafale II from scratch. Within 2 years of study and extracurricular work, Ecole de Technologie Supérieure (ETS), this university team composed of 16 university students and MSc, and determined to participate in the big leagues, designed and built the Rafale II, a composite catamaran with racing hulls. Their C-Class also features "J" carbon plates and slightly smaller than average hulls, designed to reduce drag and maximize boat flight time.

Rafale I versus Rafale II

Compared to Rafale I, Rafale II has redesigned hulls and crosspieces in pre-preg epoxy of carbon fiber, not only stiffer but also lighter than 25% and they provide 15% more displacement volume. Speed and handling have also been improved by designing lighter, stronger and more performing torches of new carbon fiber epoxy laminate pack and T-section hydrofoil blades. These provide a higher lift / drag ratio and greater stability when hydrofoiling.

The Rafale II got support from 40 sponsors, including Scott Bader who provided technical support and advanced materials. The ETS students faced a number of design challenges but had expert support and technical advice from team mentor Professor Simon Joncas (from the ETS Automated Manufacturing Engineering Department). Julien Chaussée (an aerospace engineer and former member of the team member of the British "Invictus" C-Class catamaran) and Xavier Grossmann, (structural engineer) advised the team on FEM modeling and beam optimization.

Key problem

The main problem with Rafale I, was that although the carbon fiber composite laminate used for the hulls was extremely strong, it proved too heavy for the extreme level of competition that was envisioned for the catamaran. To reduce weight, the hull had to be completely redesigned using FEA and CAD technology based on a carbon fiber epoxy pre-impregnation system for new hull laminate. The new half sections of carbon fiber epoxy hulls for Rafale II were molded with the autoclave (OoA) low pressure vacuum bag using heated tools with a mould temperature of 93 °C for 10 hours. To reduce weight, the two halves of the hull were joined together using Scott Bader's Crestabond® M1-30 structural adhesive in the second stage assembly process, as well as the new carbon fiber cross beam sections; the beams made by ply winding on extruded aluminum profiles using the same epoxy prepreg grade specified for the hulls.

The most efficient sailing machines in the world

The Rafale II, weighing no more than 220 kg, has been recommended by some sailing experts as "the most efficient sailing machines in the world", eventhough they are notoriously difficult to sail. C-Class catamarans have achieved hydrofoiling speeds on water up to 34 knots (~ 63 km/h). A C-Class catamaran literally "flies" over the water on the twin hydrofoil J shaped daggers, mounted one in each hull, along with linked T-shaped hydrofoiling rudders. Unlike a typical sailing boat, a modern C-Class catamaran does not have conventional sails, but a rigid, symmetrical wingsail, typically made from lightweight, high performance composite materials. The wingsail design developed for Rafale I and currently in use on Rafale II, has distinct sections that behave differently. The front section of the wingsail is rigid with a U-shaped front edge section reinforced with aerodynamic carbon fiber. In order to provide better aerodynamics and greater speed, the wingsail uses a 'morphing' trailing edge in the lower section of the wing as well as the movable flap upper rear section. This morphing trailing edge changes shape and flexes in response to the wind force, which results in an increased forward thrust.

Continuous improvement

While Rafale II made its debut in February 2018 at the Miami Foiling Week (not only has it been the single one student team, but also the only C-Class to participate), the ETS team is currently looking to improve the design and produce a new wingsail in time for the September 2018 race in Montreal. To conclude, ETS Rafale has been impressing us over and over again along the way.

Share your stories on leisure marine industry with us

Do you have an innovation, research results or an other interesting topic you would like to share with the leisure marine equipment industry? The METSTRADE website and social media channels are a great platform to showcase your stories! Let us know via metstrade@rai.nl

Are you a METSTRADE exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.